What is Shielding Sensor Technology in Wireless Fuel Sensor?

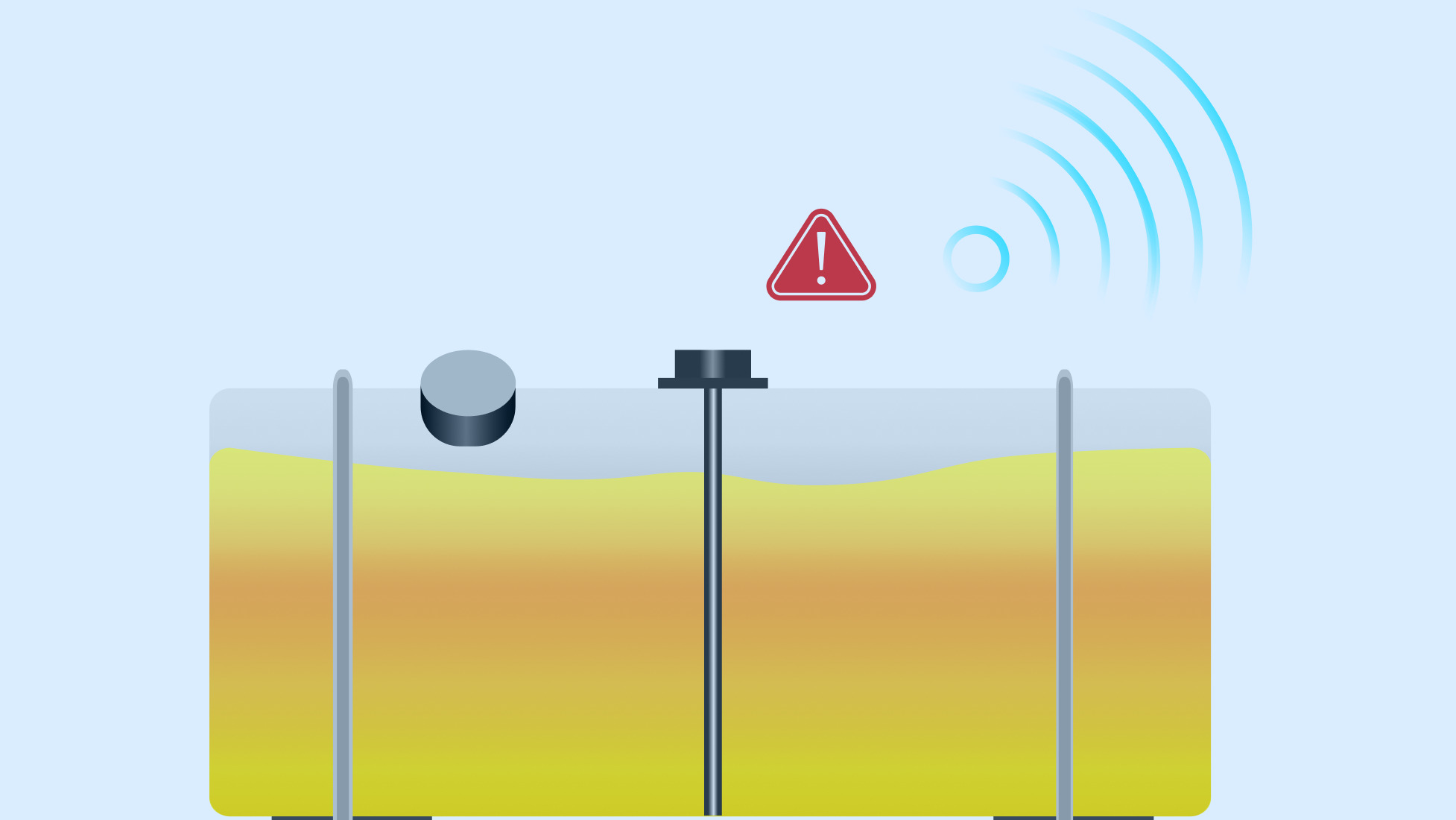

Wireless fuel sensors are at the forefront of technological innovation. They offer a seamless way to monitor fuel levels in various applications. By eliminating the need for wired connections, these sensors provide flexibility, ease of installation, and the ability to monitor remote locations. Entering the concept of shielding sensor technology. This is a revolutionary safeguard designed to protect the sensor’s data integrity against tampering or blocking attempts. This technology ensures that even when external forces attempt to disrupt the sensor’s operation, the data remains secure and intact. It acts as a fail-safe, storing information within the sensor’s internal memory for later retrieval. It also guarantees that crucial fuel level data is always accessible when needed.

Understanding Shielding Sensor Technology

At the core of wireless fuel sensor technology lies a critical component: data integrity. Shielding sensors marks a significant milestone in ensuring this integrity. Especially in environments where tampering or signal blocking attempts are prevalent. This technology isn’t just about protection; it’s about maintaining seamless operation and data reliability in the face of potential disruptions.

How Shielding Sensor Technology Works

Shielding sensor technology operates on a simple yet effective principle: safeguarding data transmission and storage in real-time. When a fuel sensor is equipped with shielding it detects an attempt to tamper with its physical structure or block its communication signals. It immediately activates its protective measures. The sensor shifts its focus to ensuring that the data it holds does not become corrupted or lost.

This is achieved through a series of sophisticated mechanisms. Firstly, the sensor temporarily halts data transmission to the central monitoring system. This pause in transmission is not a sign of defeat but a strategic move to secure the data. The sensor then encrypts and stores the current data readings in its internal memory, safeguarded by the shielding technology. This internal memory is designed to be resilient against external attacks, ensuring that data is not just stored but protected.

The Role of Internal Memory

The internal memory plays a pivotal role in the operational efficiency of shielding sensor technology. It serves as a secure vault, holding the data until it can be safely transmitted to the central system. This approach ensures that, even in scenarios where data transmission is interrupted for extended periods, no critical information is lost. Once the threat of tampering or signal blocking has passed, the sensor resumes its normal operation, decrypting and sending the stored data to the central monitoring system.

Moreover, the internal memory is equipped to handle significant amounts of data, ensuring that even prolonged attempts at disruption do not result in data loss. This capability is crucial for maintaining operational continuity and ensuring that fuel management systems remain informed and effective.

Benefits of Shielding Sensor Technology

The benefits of shielding sensor technology extend far beyond just protecting against tampering and signal blocking. By ensuring that data integrity is maintained at all times, it provides a foundation for secure and reliable fuel monitoring systems.

Furthermore, the use of shielding sensor technology significantly reduces the risk of data tampering. A concern that has grown with the increasing sophistication of cyber threats. By making it virtually impossible for unauthorized individuals to corrupt or intercept fuel data. Shielding sensors play a crucial role in cybersecurity strategies for critical infrastructure.

In summary, shielding sensor technology is a game-changer in the realm of wireless fuel sensors. It not only protects against physical and cyber threats but also ensures that critical fuel data is always available, accurate, and secure. This reliability and security are paramount in today’s fast-paced, data-driven industries, making shielding sensors an indispensable tool in the quest for operational excellence.

The Importance of Shielding in Fuel Sensors

Shielding technology is a necessity for maintaining the integrity and security of critical data in numerous industries. The importance of this technology stems from its ability to prevent tampering and data breaches. It ensures that fuel management systems are both reliable and robust.

Mitigating Risks of Tampering and Blocking

One of the primary roles of shielding sensor is to mitigate the risks associated with tampering and signal-blocking attempts. Tampering with these sensors can lead to inaccurate data, resulting in operational disruptions, financial losses, and in some cases, safety hazards.

Shielding sensor technology ensures that even if an attempt to interfere with the sensor’s operation occurs, the data remains unaltered and secure. This protective measure is critical in preventing unauthorized access to the sensor’s data, which could be used to manipulate fuel readings or disrupt operations.

Preventing Data Breaches

In addition to protecting against physical tampering, shielding technology plays a crucial role in cybersecurity. With the increasing prevalence of cyber-attacks on industrial systems, the risk of data breaches has become a significant concern. Shielding sensors ensure that data transmission between the sensor and the monitoring system is secure, reducing the risk of interception or manipulation by cyber threats.

By encrypting the data and storing it within the sensor’s protected internal memory, shielding technology provides a robust defense against cyber-attacks. This level of security is essential for industries that rely on accurate and timely data for their operations.

Ensuring Operational Continuity

Perhaps one of the most critical aspects of shielding sensor technology is its role in ensuring operational continuity. By safeguarding the sensor’s data, industries can maintain consistent and reliable operations, even in the face of attempts to disrupt the sensor’s functionality. This continuity is essential for effective fuel management, as it allows for accurate monitoring, forecasting, and planning.

Operational continuity also means that businesses can avoid costly downtime and operational inefficiencies that result from data tampering or loss. In this way, shielding sensor technology not only protects the sensor’s data but also safeguards the operational integrity of the entire fuel management system.

Operational Mechanism of Shielding Sensor

The operational mechanism of shielding sensors in wireless fuel monitoring systems is both sophisticated and robust. It is designed to ensure uninterrupted data integrity and security. This mechanism is crucial for protecting the sensor from tampering and signal blocking attempts, thereby maintaining the continuous flow of accurate and reliable data.

Immediate Response to Tampering Attempts

At the heart of the shielding sensor’s design is an immediate response system that activates the moment a tampering or blocking attempt is detected. This system is engineered to recognize any unauthorized physical or signal interference with the sensor. Upon detection, the sensor initiates a series of actions designed to secure the data it has collected.

The first step is the temporary suspension of data transmission. This is not to say the sensor goes offline. Rather, it shifts its priority to safeguarding the data already collected. By halting transmission, the sensor minimizes the risk of data being intercepted or altered during the tampering attempt.

Data Encryption and Internal Storage

Following the suspension of data transmission, the sensor encrypts the current fuel data readings. Encryption is a critical step, as it transforms the data into a format that can only be deciphered with a specific decryption key. This key is securely stored within the sensor, far from the reach of potential intruders.

Once encrypted, the data is stored in the sensor’s internal memory. This memory is not just a storage space but a fortified vault designed to withstand physical and cyber-attacks. The choice of encryption algorithms and the design of the internal memory are based on the latest cybersecurity practices, ensuring that the data remains accessible only to authorized personnel.

Resuming Normal Operations

After the threat has passed, the sensor resumes its normal operation. It decrypts the stored data and transmits it to the central monitoring system. This process ensures that no data is lost during the tampering attempt. It also ensures that fuel level readings remain continuous and accurate.

The ability to store and later transmit data ensures operational continuity, a vital aspect for industries relying on precise fuel management. It means that even in the face of attempts to disrupt the sensor’s functionality, the system remains resilient, providing consistent and reliable data.

Benefits of the Operational Mechanism

The operational mechanism of the shielding sensor offers numerous benefits, including enhanced security, operational reliability, and data integrity. By protecting the sensor from tampering and signal-blocking attempts, industries can trust the accuracy and reliability of their fuel monitoring systems. This trust is crucial for making informed decisions, optimizing fuel consumption, and planning logistics.

Furthermore, the mechanism’s design reflects a proactive approach to cybersecurity, acknowledging and addressing the evolving landscape of threats. This approach not only protects the sensor and its data but also contributes to the overall security of the operational environment.

Conclusion

As we’ve explored, this technology safeguards critical fuel data against tampering and unauthorized access. It also ensures operational continuity and efficiency across a variety of industries. From logistics and transportation to aviation and construction, the applications of shielding sensors are vast and impactful.

The challenges of implementing this technology, while significant, are surmountable with strategic planning, training, and adaptation. Looking ahead, the future promises even more robust, user-friendly, and integrated shielding solutions. It makes secure and reliable fuel monitoring accessible to an even wider audience.

For industries reliant on accurate fuel data, the message is clear. Embracing shielding sensor technology is not just an investment in data security. It’s a commitment to operational excellence and long-term sustainability. As technology continues to evolve, staying ahead of the curve with solutions like shielding sensors will be key to navigating the challenges of the modern world and securing a competitive advantage.

In summary, shielding sensor technology is more than an innovation; it’s a necessary evolution in the quest for secure, efficient, and reliable fuel management.