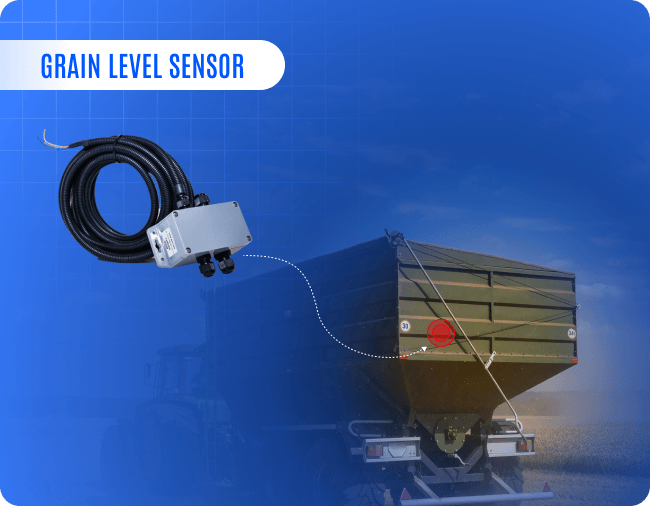

The harvest sensor or grain level sensor, streamlines agricultural operations by offering precise control of container dynamics as levels change during filling. Its real-time monitoring allows for efficient management of grain volumes, ensuring accuracy in yield tracking and resource allocation in agro-industrial production. Easy to install on various machinery, it supports automated grain accounting and control.

Grain Level Sensor

Track grain levels in real time with high-precision sensing hardware. Designed for silos, hoppers, and bulk containers