This sensor offers high-quality performance and value. It’s designed with a standardized measurement part length of 990mm for versatile use. Installation is easy with its universal connector. It features configurable frequency output and RS485 digital interface with LLS protocol support. This allows customized control systems. They are versatile to fit any industry.

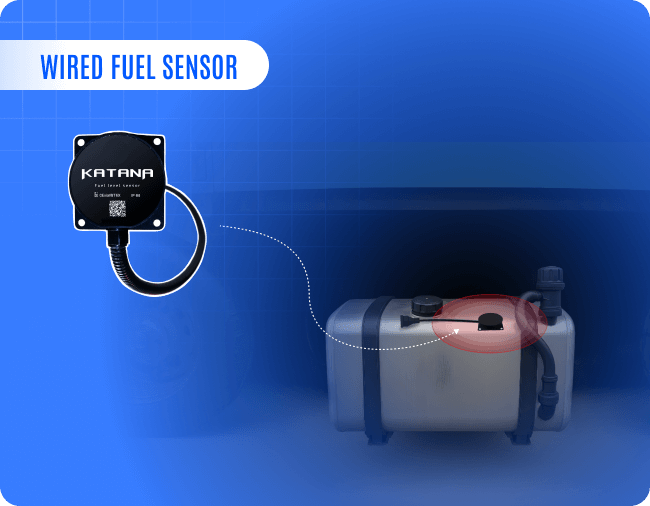

Wired Fuel Level Sensors

High-Precision Fuel Tracking Built for Demanding Environments Get accurate, real-time fuel level data with our rugged wired sensors - ideal for generators, heavy vehicles, and industrial machinery.