The mining industry relies heavily on fuel-powered machinery and vehicles for excavation, transportation, and processing operations. Managing fuel consumption effectively is crucial for minimizing operational costs and environmental impact. Wired fuel level sensors provide real-time data on fuel levels, consumption rates, and refueling events, enabling precise monitoring and management of fuel resources.

Introduction

Challenges

High Fuel Consumption: Mining operations involve heavy machinery that consumes large amounts of fuel, making fuel one of the largest operational expenses.

Fuel Theft and Fraud: Without precise monitoring, the risk of fuel theft or fraud increases, leading to significant financial losses.

Operational Inefficiencies: Inefficient fuel usage can result from poor monitoring and management, affecting overall productivity and increasing costs.

Environmental Concerns: Excessive fuel consumption contributes to higher emissions, impacting environmental sustainability goals.

Maintenance and Downtime: Unmonitored fuel levels can lead to unexpected machinery downtime, affecting operational efficiency and increasing maintenance costs.

Challenges

Solution

Wired fuel level sensors in mining sector provide a comprehensive solution to these challenges by offering the following capabilities:

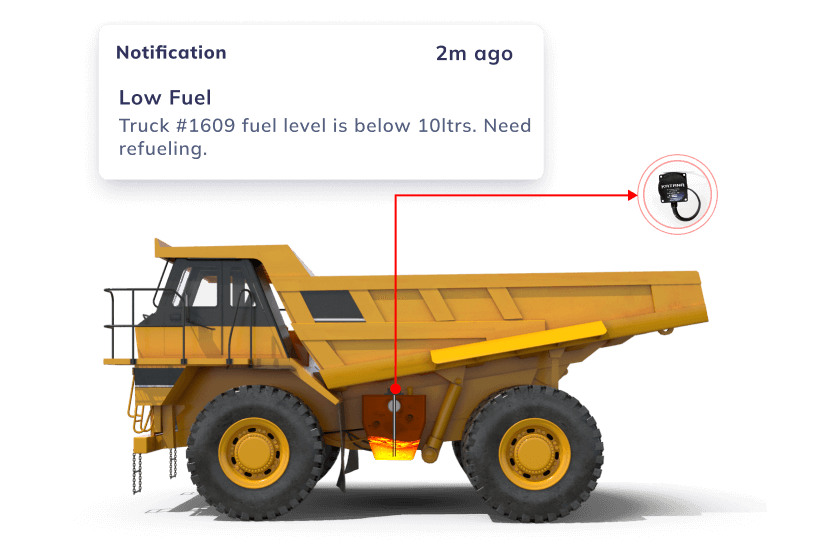

Real-time Fuel Monitoring: They enable continuous monitoring of fuel levels in machinery and storage tanks, providing instant alerts on critical levels or discrepancies.

Theft and Leakage Detection: Advanced algorithms can detect unusual drops in fuel levels, indicating potential theft or leakage, and alert management immediately.

Efficiency Analysis: By analyzing fuel consumption patterns, companies can identify inefficiencies in machinery usage and operational practices, leading to more informed decision-making.

Predictive Maintenance: Monitoring fuel consumption can also help in predicting maintenance needs, reducing unexpected downtime.

Environmental Compliance: Accurate fuel usage data supports compliance with environmental regulations by enabling more efficient fuel use and reducing unnecessary emissions.

Results

Implementing wired fuel sensors in the mining industry leads to several tangible benefits:

Reduced Fuel Costs: By minimizing theft, leakage, and inefficiencies, companies can significantly reduce their fuel-related expenses.

Increased Operational Efficiency: Real-time data allows for better resource allocation, improved scheduling, and minimized downtime, enhancing overall productivity.

Enhanced Environmental Sustainability: Efficient fuel use contributes to lower carbon emissions, aligning with environmental sustainability goals.

Improved Maintenance Schedules: Predictive maintenance based on fuel consumption patterns can extend the lifespan of machinery and reduce maintenance costs.

Data-Driven Decision Making: The wealth of data provided by fuel level sensors supports informed decision-making, optimizing operational strategies, and resource management.