The agriculture industry heavily relies on machinery for planting, tending, and harvesting crops. Fuel-powered machinery such as tractors, harvesters, and irrigation pumps are essential for these operations. Efficient fuel management is crucial for ensuring these machines operate smoothly without unnecessary downtime. wireless fuel level sensors stand out as a pivotal tool for enhancing the efficiency and reliability of agricultural operations.

Introduction

Challenges

Manual Monitoring Inefficiencies

Traditionally, monitoring fuel levels in agricultural equipment has relied heavily on manual inspection. Manual checks are prone to inaccuracies. It leads to unexpected machinery downtime due to unforeseen fuel shortages.

Fuel Theft and Misuse

In the absence of real-time monitoring capabilities, agricultural operations face heightened risks of fuel theft and misuse. This lack of oversight compromises the security of fuel supplies.

Operational Inefficiencies

Without accurate and timely data on fuel consumption, optimizing fuel usage across various types of machinery and operations becomes a challenge.

Maintenance and Downtime

Inefficient fuel management not only affects operational costs but also contributes to increased wear and tear on machinery. This necessitates more frequent maintenance, potentially leading to longer periods of downtime and disrupting agricultural productivity.

Challenges

Solution

Our wireless fuel level sensors offer an effective solution to these challenges, equipped with features that enhance fuel management across agricultural operations:

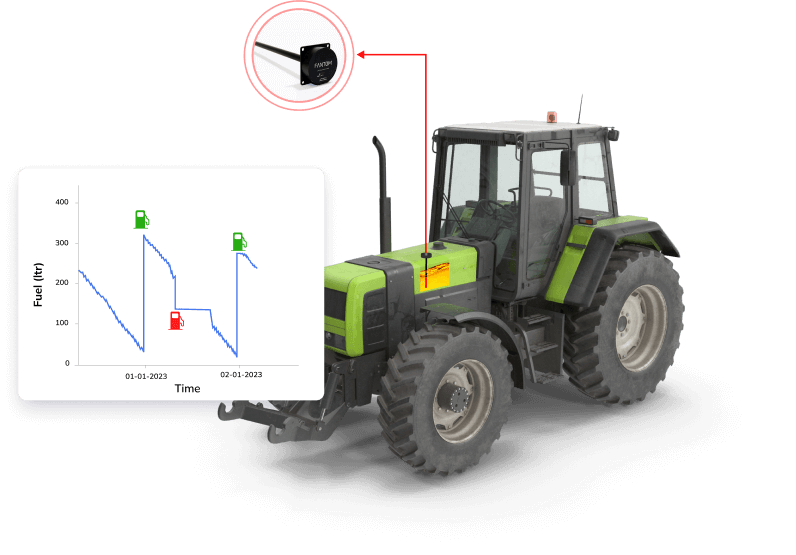

Instant Alerts and Real-Time Monitoring: Operators receive immediate notifications about critical fuel levels, potential leaks, or unauthorized fuel usage. It allows for prompt action to mitigate these issues.

Universal Fuel Compatibility: These sensors are designed to work with a broad spectrum of fuels used in agriculture. This ensures accurate monitoring regardless of the fuel type. This flexibility is crucial for farms that operate a diverse fleet of machinery.

Data-Driven Fuel Management: The sensors provide valuable data on fuel consumption patterns. This enables farm managers to analyze usage trends. They can plan efficient refueling schedules, and make informed decisions on fuel procurement.

Minimization of Operational Downtime: Real-time fuel data are received from wireless fuel sensor for agriculture. Due to this machinery can be refueled proactively. This avoids unexpected stops and keeps operations running smoothly.

Results

The adoption of wireless fuel level sensor for agriculture industry yields significant benefits:

Reduced Operational Costs: Efficient fuel management leads to considerable savings by minimizing waste and unnecessary expenses associated with fuel consumption.

Increased Productivity: By reducing downtime and ensuring that machinery is readily available when needed, these sensors contribute to higher overall operational efficiency.

Enhanced Security: Improved monitoring capabilities help prevent fuel theft and misuse, securing valuable resources and ensuring their optimal use.

Sustainability: Optimizing fuel consumption contributes to reducing the environmental impact of agricultural operations, aligning with broader sustainability goals.