Dairy products are highly perishable and require strict temperature control from the point of production to the point of consumption. The temperature-sensitive nature of these products demands precise monitoring during transportation to prevent spoilage, bacterial growth, and to comply with food safety regulations. Temperature sensors are crucial in this logistic chain, providing real-time data to ensure that dairy products are transported within their required temperature ranges.

Introduction

Challenges

Implementing a comprehensive cold-chain monitoring solution with advanced temperature sensors and robust data management systems can lead to:

Enhanced Product Integrity: Ensuring products remain within their required temperature range throughout the supply chain significantly reduces spoilage and loss.

Regulatory Compliance: Efficient monitoring and reporting facilitate adherence to global regulatory standards, avoiding costly fines and reputational damage.

Operational Efficiency: Real-time monitoring and data analysis can identify inefficiencies within the cold chain, allowing for timely interventions and optimizations.

Customer Trust: Demonstrating a commitment to maintaining product quality through rigorous cold-chain monitoring enhances consumer and partner trust. This leads to stronger relationships and business growth.

Challenges

Solution

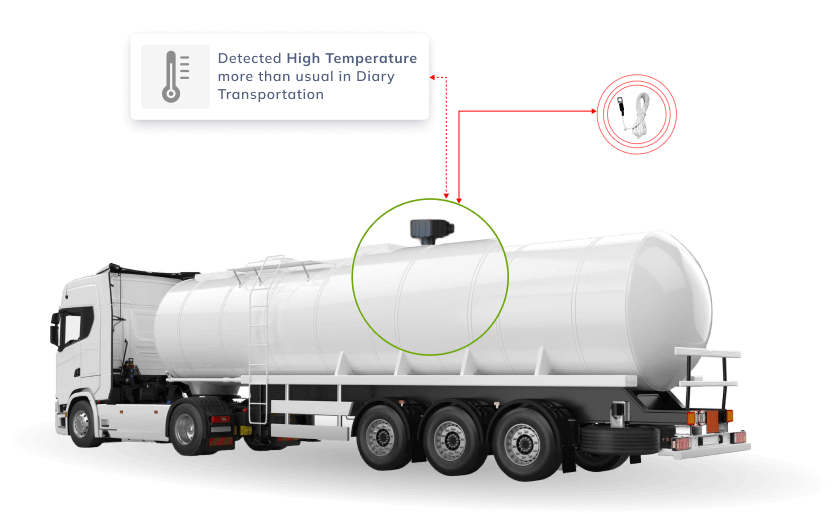

Advanced Temperature Sensors: The use of advanced temperature sensors that provide real-time, accurate temperature readings is crucial. These sensors can be integrated with IoT technology for continuous monitoring and data logging throughout the transportation process.

Automated Alerts: Systems that automatically alert operators when temperatures deviate from the set thresholds help in taking immediate corrective actions, preventing spoilage.

Predictive Maintenance: Implementing predictive maintenance for refrigeration equipment based on data collected from temperature sensors can help in identifying potential failures before they occur.

Cloud-Based Data Management: Utilizing cloud-based platforms for storing and managing temperature data ensures easy access for compliance reporting and quality control analysis. This approach also facilitates remote monitoring capabilities.

Results

Implementing temperature sensor for dairy transportation has led to several positive outcomes:

Improved Product Quality and Safety: Continuous monitoring has significantly reduced the risk of spoilage and ensured that dairy products reach consumers in the best possible condition.

Compliance with Food Safety Standards: Receiving data from temperature sensor for dairy industry helps the software in generating reports. They have simplified compliance with food safety regulations, reducing the risk of fines and product recalls.

Reduced Losses: The ability to take immediate corrective actions in response to temperature deviations has reduced losses due to spoilage.

Enhanced Efficiency: Predictive maintenance through temperature monitoring minimizes equipment downtime. It improves the efficiency of the transportation process.