Cold-chain monitoring involves the management of a temperature-controlled supply chain to preserve, extend, and ensure the shelf life of temperature-sensitive products. Temperature sensors are integral to this process, providing real-time data to monitor the condition of the products from the point of origin through to the final destination. This data is critical in ensuring that the products remain within their required temperature range, preventing spoilage, loss of efficacy in pharmaceuticals, and ensuring compliance with regulatory standards.

Introduction

Challenges

Temperature Variability: The most significant challenge in cold-chain monitoring is maintaining consistent temperature throughout the transportation and storage processes.

Data Management: Collecting, storing, and analyzing the vast amounts of data generated by temperature sensors can be overwhelming. Ensuring data accuracy, integrity, and timely access for decision-making poses significant challenges.

Infrastructure and Cost: Implementing a comprehensive cold-chain monitoring system requires substantial investment in infrastructure, including advanced temperature sensors, data loggers, and a robust IT system for data analysis and reporting.

Regulatory Compliance: Adhering to the stringent regulations and standards set by various health and food safety authorities worldwide requires meticulous monitoring and reporting processes, adding another layer of complexity to cold-chain management.

Challenges

Solution

To address these challenges, a multi-faceted approach is required, including:

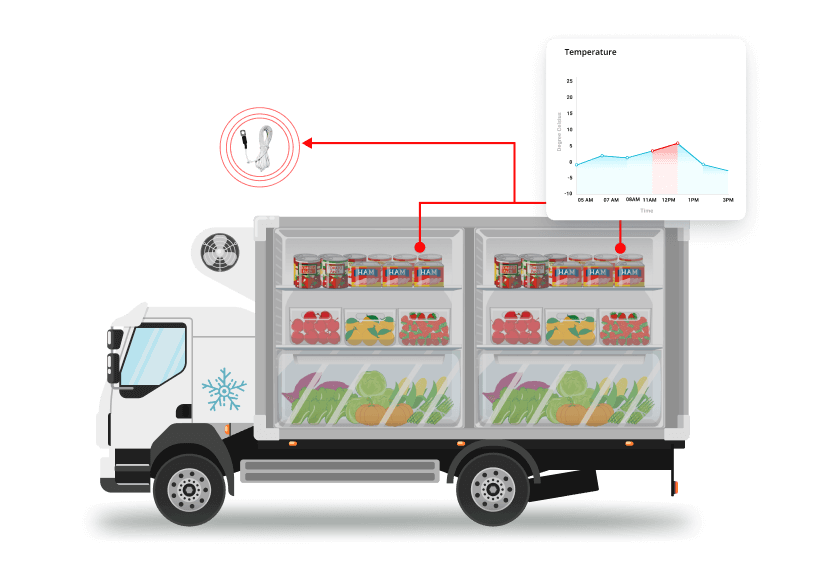

Advanced Temperature Sensors: Utilizing high-quality, accurate, and reliable temperature sensors capable of providing real-time data is fundamental. Sensors with remote monitoring capabilities allow for immediate alerts in case of temperature deviations.

Integrated Data Management Systems: Implementing a centralized data management system that can collect, store, and analyze data from temperature sensors in real-time. This system should provide actionable insights and facilitate compliance with regulatory reporting requirements.

Robust Infrastructure: Investing in the necessary infrastructure, including temperature-controlled storage units and transportation vehicles equipped with advanced temperature monitoring systems, ensures the integrity of the cold chain.

Training and Protocols: Establishing clear protocols for responding to temperature excursions and training staff on the importance of maintaining the cold chain can significantly mitigate human error and equipment misuse.

Results

Implementing a comprehensive cold-chain monitoring solution with advanced temperature sensors and robust data management systems can lead to:

Enhanced Product Integrity: Ensuring products remain within their required temperature range throughout the supply chain significantly reduces spoilage and loss.

Regulatory Compliance: Efficient monitoring and reporting facilitate adherence to global regulatory standards, avoiding costly fines and reputational damage.

Operational Efficiency: Real-time monitoring and data analysis can identify inefficiencies within the cold chain, allowing for timely interventions and optimizations.

Customer Trust: Demonstrating a commitment to maintaining product quality through rigorous cold-chain monitoring enhances consumer and partner trust, leading to stronger relationships and business growth.