Dump trucks operating in quarries and construction sites face the constant risk of rollovers during unloading, especially on uneven terrain. This not only poses a significant danger to personnel but also leads to potential equipment damage and operational delays.

Introduction

Challenges

Operational Inefficiency: Without a tilt sensor, tracking the exact number of dumps and the duration of each dump can be challenging. It leads to inefficiencies in operation and scheduling.

Safety Risks: Operators lack real-time information on the bed angle. This increases the risk of over-tilting and potential accidents or vehicle damage.

Lack of Accountability: It’s difficult to verify operations and ensure that all unloading activities are completed as scheduled without accurate records.

Increased Maintenance: Without data on the frequency and intensity of the dump truck’s use, predictive maintenance is hindered, potentially leading to unexpected breakdowns.

Challenges

Solution

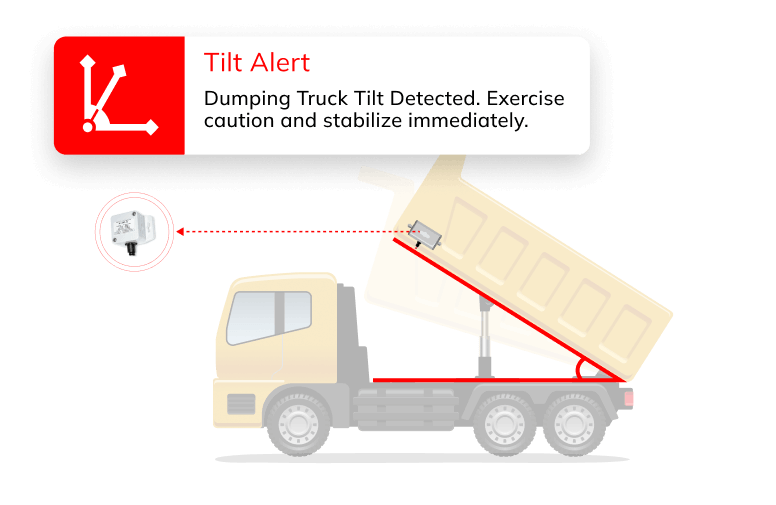

Implementing a tilt sensor system integrated with GPS tracking software provides a cost-effective, efficient solution. Tilt sensors measure the dump truck’s angle in real-time during unloading.

Detailed Reporting: The sensor reports every time the bed moves up to dump its load, providing data on when the action took place, how long it took, and how many dumps were performed.

Operational Insights: Each rollover of the dump truck’s body is reported, including the start and end of the body operation, the amount, and the duration of the unloading cases.

Safety Enhancements: Real-time monitoring of the bed’s angle ensures operations are conducted within safe limits, reducing the risk of tipping.

Maintenance Scheduling: The logged data can be used to better schedule maintenance based on actual usage, potentially extending the truck’s lifespan and reducing costs.

Solution

Results

Enhanced Safety: Significantly reduced the risk of rollovers, protecting drivers and onsite workers.

Operational Efficiency: Minimized downtime and disruptions, ensuring smoother project timelines.

Cost Savings: Avoided expensive solutions and equipment damage, improving overall profitability.