Excavators are integral to construction, mining, and excavation projects. Precise control and operational efficiency are vital for project success and profitability. Tilt sensors offer a way to improve the control and monitoring of excavator arms, leading to better performance and reporting.

Introduction

Challenges

Imprecise Operations: Without a tilt sensor, operators may not be able to judge the exact angle of the excavator’s arm and bucket. This may lead to imprecise digging and material handling.

Safety Concerns: An excavator operating on uneven terrain without tilt monitoring can become unbalanced. This increases the risk of accidents or tipping over.

Manual Monitoring: Operators would need to rely on visual cues and personal judgment, which can be exhausting and less reliable, especially over long working hours.

Productivity Loss: Without accurate angle data, repetitive tasks may take longer to perform. It leads to a loss in productivity and operational inefficiency.

Challenges

Solutions

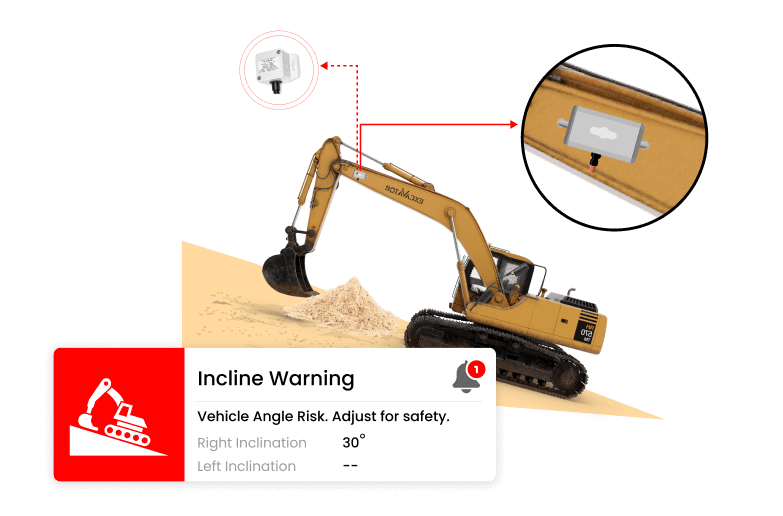

Tilt Sensor Installation: Attach robust tilt sensors on the excavator arm to provide real-time data on its position and movement.

Real-time Angle Monitoring: It continuously measures the tilt angle of the excavator’s equipment. This provides real-time data to the operator for precise movement and digging.

Operational Efficiency: Knowing the exact angle of the boom and bucket improves the operator’s control over digging and material handling tasks. It leads to more efficient operations.

Safety Improvements: The sensor helps ensure that the excavator is operating within safe tilt limits, reducing the risk of accidents related to equipment instability.

Energy and Time Saving: With more precise control, there’s less need for corrective actions, which saves on operational time and can lead to energy savings.

Challenges

Results

Operational Precision: Improved accuracy and precision in excavation tasks.

Efficiency Gains: Reduced idling times and enhanced time management on projects.

Safety Improvements: Increased operator and site safety with real-time tilt monitoring.

Cost Reduction: Lower operational costs through better fuel management and reduced equipment wear.