In modern farming, maximizing efficiency and productivity while minimizing costs and environmental impact is essential. The agriculture industry relies heavily on various types of machinery like tractors, combines, sprayers, and harvesters, all of which require robust tire management to perform optimally. Tire Pressure Monitoring Systems (TPMS) offer a technological advantage by ensuring that tires are kept at their ideal pressure for various agricultural tasks.

Introduction

Challenges

Soil Compaction: Inappropriate tire pressure can lead to soil compaction, which hinders root development and decreases crop yields.

Irregular Tire Wear: Tires operating without optimal pressure are prone to irregular wear, shortening tire life and leading to frequent replacements.

Variable Tire Pressure Requirements: Agricultural equipment requires different tire pressures for field operations versus traveling on roads, making manual adjustments time-consuming and often overlooked.

Increased Maintenance: Without TPMS, tire maintenance relies on manual checks. This are less frequent and can result in overlooking slow leaks or minor damages that can escalate into major issues.

Seasonal Work Windows: Agricultural tasks are highly time-sensitive, with narrow windows for planting and harvesting. Equipment downtime due to tire issues can have significant impacts on productivity.

Fuel Consumption: Tires that are not at their optimal pressure increase rolling resistance, leading to higher fuel consumption and increased operational costs.

Challenges

Solution

Implementing TPMS in agricultural machinery offers several benefits:

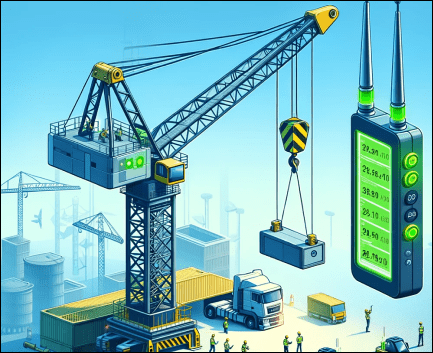

Automated Pressure Monitoring: TPMS continuously monitors tire pressure, ensuring that tires are always at the correct pressure for the job, whether in the field or on the road.

Early Problem Detection: TPMS can alert operators to pressure drops due to punctures or leaks, allowing for timely repairs before significant damage occurs.

Optimized Fuel Usage: Proper tire inflation as monitored by TPMS can improve fuel efficiency, reducing overall fuel costs.

Reduced Soil Damage: By maintaining the correct tire pressure, TPMS helps minimize soil compaction, preserving the soil structure and health.

Extended Tire Life: Correct tire pressure reduces uneven wear and extends the life of the tires, lowering replacement costs.

Challenges

Results

Decreased Operational Costs: Savings from reduced fuel consumption and tire replacement costs directly improve the bottom line.

Improved Equipment Uptime: Minimized tire-related downtime keeps machinery in operation during critical periods, maximizing productivity.

Enhanced Safety: Real-time alerts on tire health can prevent accidents caused by tire failure, enhancing the safety of equipment operators.

Data-Driven Insights: The data collected from TPMS can inform better tire maintenance schedules and investment decisions in high-quality tires suited for agricultural use.