The transportation and logistics industry is critical for the global economy. It relies heavily on trucks, trailers, and commercial vehicles to move goods efficiently. The performance and safety of these vehicles are significantly influenced by the condition of their tires. Tire Pressure Monitoring Systems (TPMS) offer a crucial advantage by ensuring tires are maintained at optimal pressure, enhancing safety, efficiency, and reliability in logistics operations.

Introduction

Challenges

Increased Tire Wear: Improper tire pressure can lead to uneven or accelerated tire wear. It necessitates more frequent replacements and increasing operational costs.

Fuel Inefficiency: Over- or under-inflated tires can decrease fuel economy due to higher rolling resistance. It impacts overall efficiency and environmental footprint.

Safety Risks: Incorrect tire pressure is a major contributor to tire blowouts and failures, which can lead to dangerous accidents and jeopardize the safety of drivers and other road users.

Downtime and Delays: Tire issues can cause unexpected downtime. It may result in delays that disrupt delivery schedules and affect customer satisfaction.

Maintenance Costs: Without TPMS, detecting and addressing tire issues relies on manual inspections, which can be inconsistent and lead to overlooked tire maintenance needs.

Load Carrying Inefficiencies: Improper tire pressure affects a vehicle’s ability to carry loads efficiently. It potentially leads to underperformance and increased wear on vehicle components.

Challenges

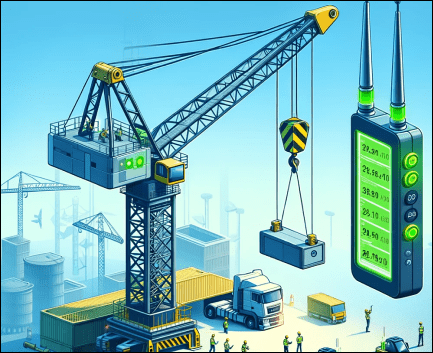

Solution

Implementing TPMS in transportation and logistics vehicles addresses these challenges effectively:

Optimal Tire Pressure Maintenance: TPMS continuously monitors tire pressure, ensuring tires are properly inflated, which extends their lifespan and reduces the need for replacements.

Improved Fuel Economy: By maintaining the correct tire pressure, TPMS helps vehicles achieve better fuel efficiency, lowering operational costs and reducing the environmental impact.

Enhanced Safety: Real-time monitoring and alerts help prevent tire-related accidents, improving the safety of transport operations.

Reduced Downtime: Early detection of tire pressure issues allows for timely maintenance, minimizing unexpected breakdowns and keeping deliveries on schedule.

Lower Maintenance Costs: Automated monitoring reduces the reliance on manual inspections, cutting down maintenance costs and ensuring more consistent tire care.

Increased Load Efficiency: Proper tire inflation supports optimal load distribution and vehicle performance, enhancing overall operational efficiency.

Challenges

Results

Cost Savings: Significant reductions in fuel consumption and tire replacement costs contribute to overall operational savings.

Operational Reliability: Reduced downtime and fewer tire-related incidents lead to more reliable service and improved customer satisfaction.

Safety Improvements: A decrease in tire-related accidents enhances driver safety and reduces the risk of costly liabilities.

Environmental Benefits: Improved fuel efficiency translates to lower greenhouse gas emissions, supporting sustainability goals.